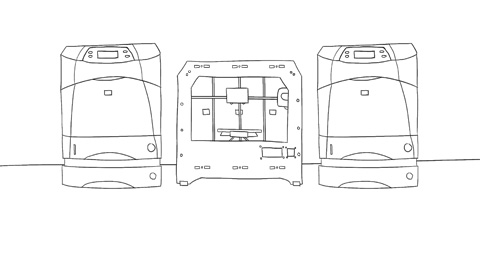

For the past year, Marlborough School has considered introducing 3D printers to campus for the sake of enriching the curriculum. After much deliberation, the School recently purchased two of these printers which are now located in visual arts instructor Kathy Rea’s classroom.

Two years ago, Rea sent an email to all faculty members, asking whether anyone was interested in having and using a 3D printer on campus. According to Rea, at the time the printers were very expensive, ranging from between $12,000 and $15,000. The high cost, combined with questions about the relevance of 3D printers to the School’s curriculum and the fact that few teachers knew how to operate the machinery, stopped the School from purchasing a 3D printer.

“We’re not going to get a 3D printer and then try and figure out how to use it, which a lot of schools have done. They buy five of these things, and then they’re sitting there, and nobody’s using them,” Director of Academic and Administrative Technology Stuart Posin said.

Recently, 3D printers have grown in popularity, and many companies, such as MakerBot Industries, are currently selling the printers for a little over $2000.

The other issues that Posin cited two years ago still stand, however.

While faculty could be taught how to use the 3D printers and their software, there is still the question of whether or not 3D printers would or could be effectively incorporated into Marlborough’s curriculum. A few teachers, including Rea and science instructor Andrew Witman, have figured out how to integrate 3D printers into some of their classes.

Rea said that she wanted to talk to Posin about purchasing a 3D printer this spring for her Architecture class so that students could make model buildings. Witman has ideas for how to integrate the 3D printer into the Applied Engineering class and Robotics Club, where students could use a 3D printer to generate parts for their robots.

“You can identify a problem on a robot, and maybe there’s not a specific piece that you have that can do all the things that you want it to do, so you can design a custom part on a computer and then 3D-print it and put it on the robot,” Witman explained.

Rather than simply incorporating 3D printers into current classes, Rea has also proposed the creation of a new course in which students would think up, design, and create objects on a computer and then print their designs using a 3D printer.

“It’s a course that could be cross-discipline. It could gather students that aren’t just art students but could be science and math people,” Rea explained. “It would be for students if they have an idea for something they’ve invented or something they would like to design and create, but maybe don’t have the technical skills with typical materials like wood or glass or plastic or ceramics.”

Some students, such as Michelle ’16, have thought of ways to incorporate 3D printers into the everyday life of the School.

“The printer could actually be used for other classes, like say history class, to build a model of something like the Colosseum.” she said.

Grace ’14 believes that the School should offer more courses that incorporate 3D printers.

“It would make our programs more special, because I know that not many schools have 3D printers,” she said.

For better or worse, 3D printers have started to revolutionize manufacturing, medicine, and other fields. People are printing out prosthetics, human bones and organs, clothes, parts for vehicles, and much more.

Despite the array of potential advantages and advances that 3D printers help to create, there are risks. Currently, much debate about 3D printers centers on the printing of plastic guns and other weapons.

The “Liberator,” one of the most popular 3D-printed plastic guns to date, was first designed and created by Defense Distributed, a libertarian, nonprofit digital publisher and 3D printing R&D firm. Defense Distributed successfully and legally created the Liberator without violating the Undetectable Firearms Act. The gun can be printed anywhere by anyone who owns a 3D printer and has access to the blueprints, which are available online.

The potential risks or 3D printing haven’t gone unnoticed by the Marlborough community, but many students and faculty think the benefits of the printers would outweigh the risks.

“I think [3D printing is] just something we have to be responsible humans about,” Posin said. “Just because some people may do something doesn’t mean that the rest of us shouldn’t enjoy the benefit of it.”